|

project: measuring RMS current with ACS712 Hall effect sensor

and Bolt 18F2550 system.

Author: Moisés Meléndez Reyes

Overview :

Allegro MicroSystems' ACS712 integrated circuit,

allows measurement of current -direct or alternating- flowing in

a conductor.

The desired measured current generates a magnetic field which

the sensor converts to a proportional output voltage,

using the Hall effect.

This voltage in turn is read by a microcontroller system through an A/D

converter to calculate its peak value and the corresponding RMS

value of the load current.

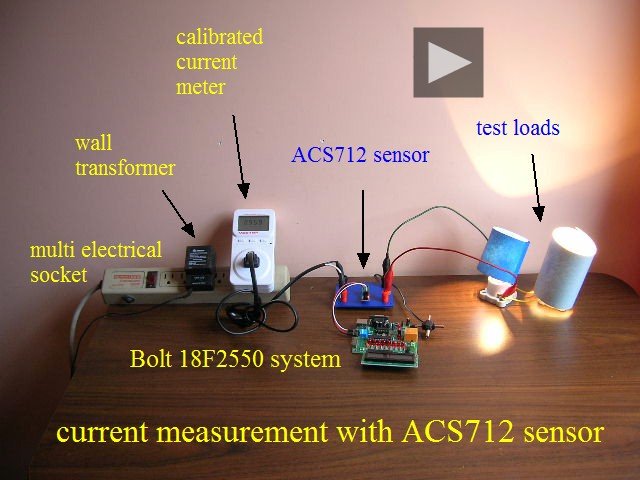

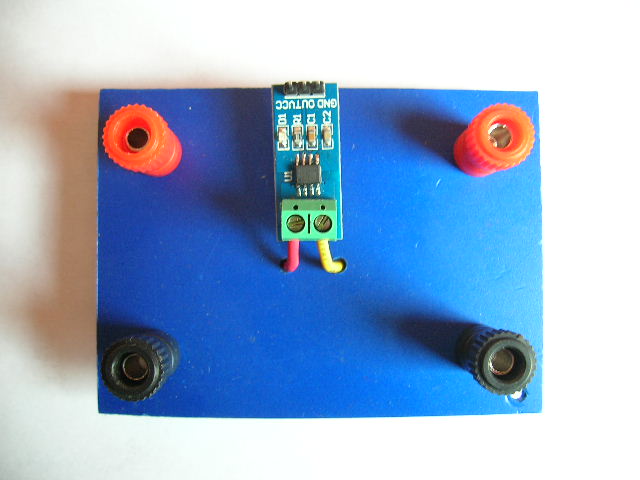

For this project, the test equipment shown in the photo above

was used.

A program in ANSI C for Bolt 18F2550

system, which reads the analog voltage signal generated by

the sensor and displays the ACS712 Irms value in its LCD was

developed.

In tests, a maximum error of 2% in the measurement is obtained by comparing

the values read through the ACS712 and the calibrated current

meter.

As test loads, three 60 watts incandescent bulbs connected in parallel were

used. The project tests took place in Mexico, where the

delivered residential power is 117 VAC, 60 Hz.

There are 3 versions for the ACS712 sensor, for ranges of 5, 20

and 30 amperes.

In the current project the sensor range is 5 amperes, with a sensitivity of

0.185 volts/ampere.

The photos displayed immediately give details of each of the

project components:

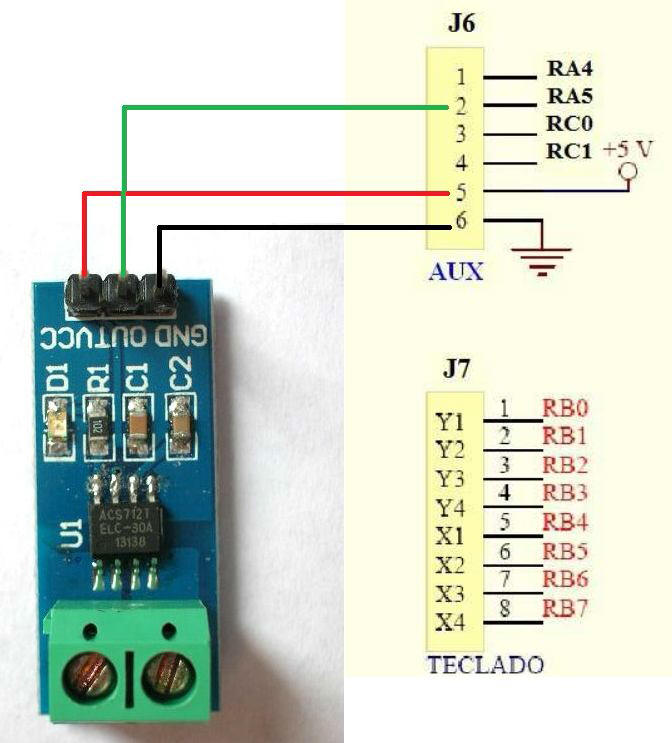

1. ASC712 current sensor:

In the

picture, the ACS712

module is shown

and allows connection

to the measuring system in a

simple and safe way: on one side,

the module has connector

screws which

connect to the

power cable terminals.

At the

other end of the module, there is a

3-pin connector, which must be

coupled to the system

microcontroller 18F2550.

Importantly, there is complete

electrical isolation between the

measured current and the

output voltage of the sensor. |

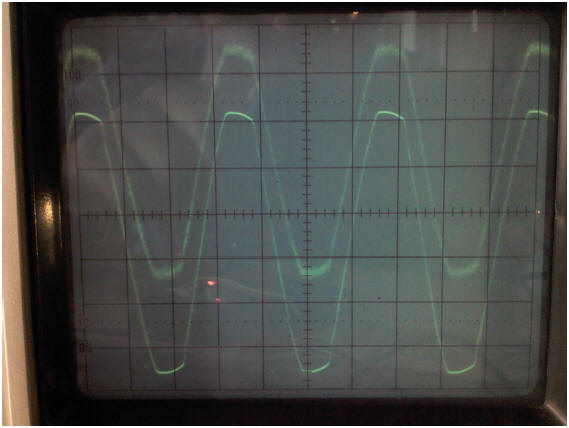

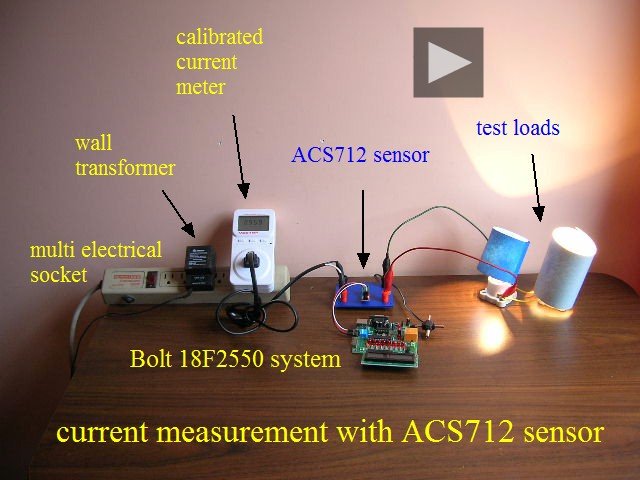

2. Osciloscope readings:

By

observing in the two channels

of an oscilloscope both the

voltage from

117 Vrms mains

and the output signal

from the ACS712 sensor, the

picture shown above is

obtained.

In the picture, the upper signal

is the voltage output

of the sensor ACS712,

(pin 'OUT')

corresponding to a a load current

of about 1 ampere (2

bulbs of 60

watts each). The

signal shown below

is the supply voltage of 117

Vrms.

The sensor signal comprises

a DC component

with a value

of Vcc/2,

in this case approximately

2.5 volts,

plus an AC component

which is directly proportional to

the current to be measured

(the datasheet

of ACS712 shows a

sensitivity is 0.185

volts/ampere, for the

sensor with

a range of 5

amps, which is

being used in this project) |

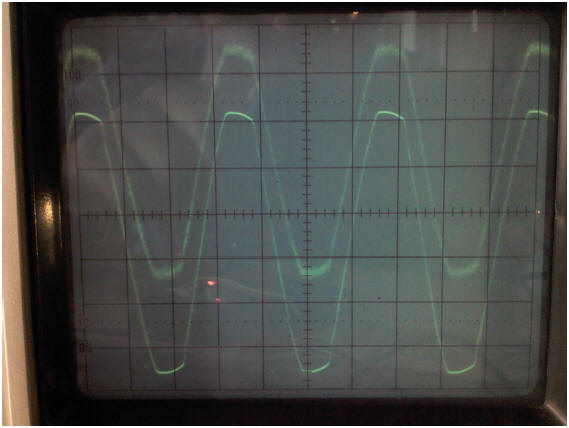

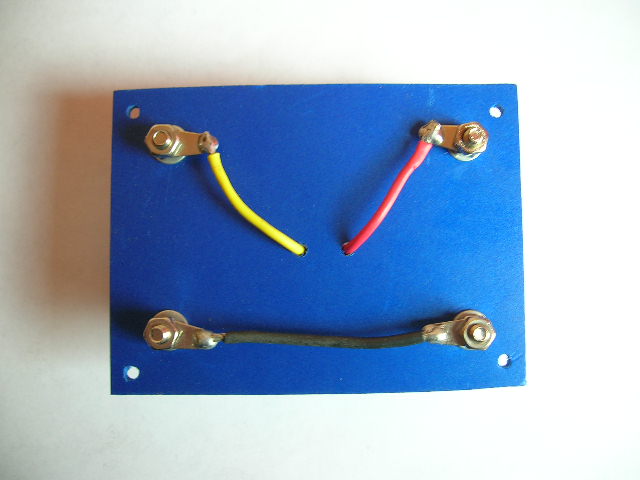

3. Preparing adecuate connections for ACS712:

To make

the connection safely

between the sensor

ACS712, the microcontroller

so as to

the 127 VAC load, a

special mount for the

circuit is made.

The

current to be measured flows

through the red terminals,

and through the ACS712 sensor,

while the return cable

is connected to the black

terminals.

|

4. Preparing adecuate connections for ACS712 (2):

Back view of ACS712 mounting plate.

|

|

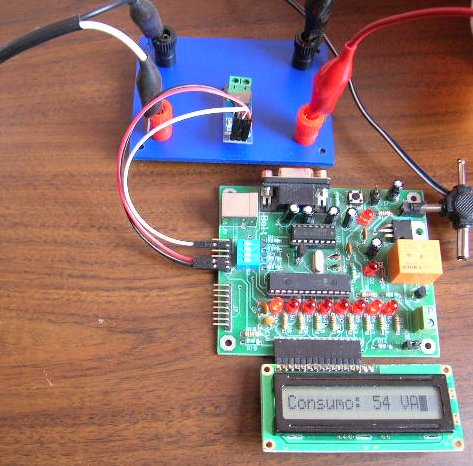

5. Connection of ACS712 and Bolt 18F2550 system:

Bolt

18F2550 microcontroller

system, fed from a wall

transformer is connected to the

ACS712 sensor module using

the electronic diagram shown

on the right. The analog

signal generated by the sensor

is input to pin

RA5 of

18F2550.

|

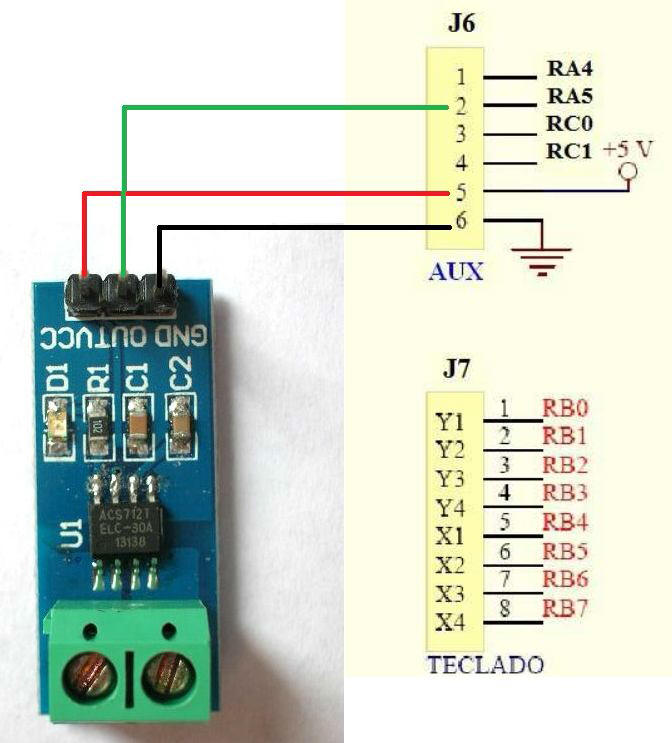

6. Electronic diagram of ACS712 and

microcontroller:

Electronic

diagram of the connections

between Bolt 18F2550

microcontroller system, and

the ACS712 sensor.

The RA5

pin signal on the

auxiliary port is in turn fed to

an A/D converter in the

18F2550.

|

|

7. Test loads using 60 watts incandescent bulbs:

As tests load for this project, two incandescent bulbs of 60

watts each were used, for a total load power of about 120 watts.

|

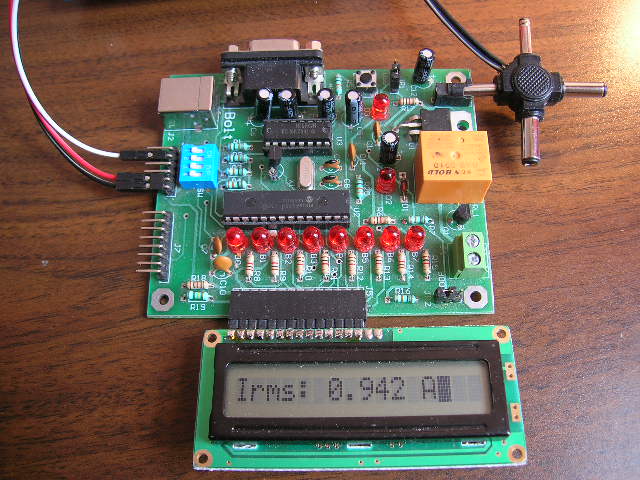

8. Bolt 18F2550 measuring Irms current:

Using the

Bolt 18F2550 system

with a program

developed in

ANSI C,

with the C18 compiler,

the 18F2550

reads the signal from the

sensor through its

A/D converter and calculates

its peak value.

Subsequently, applying arithmetical formulas,

the Irms

value of the current is calculated

as well as consumption in VA.

In this

reading, for a load of 120

watts, a

value of 0.942 amperes of

Irms was obtained. |

|

9. Calibrated current meter:

During

testing, a calibrated current

meter was used to perform

comparison with

the readings

obtained by the microcontroller

system. Here, a

reading for a load of

120 watts (2 bulbs of

60 watts), with a value of

0.962 amperes

is shown.

The

comparison of the two readings

gives an error of about

2% for the measurement obtained

with the microcontroller system,

using the following formula: E =

(0.020/0.942) * 100 = 2.12%

|

Firmware for Bolt 18F2550:

|

For the the firmware development, MPLAB-IDE v.8.89

and C18 compiler v.3.42 were used. The folder containing all files

and libraries is given below (for the moment, comments in this files

are in spanish):

Program-Bolt-C18-sensor-ACS712.zip |

Watch video!

|

|