Demonstrative

equipment of a digital automatic level control

of water, with the RG-1045S sensor

and Bolt 18F2550 system.

Project development: Moisés Meléndez Reyes

Demo Video in HD:

General description:

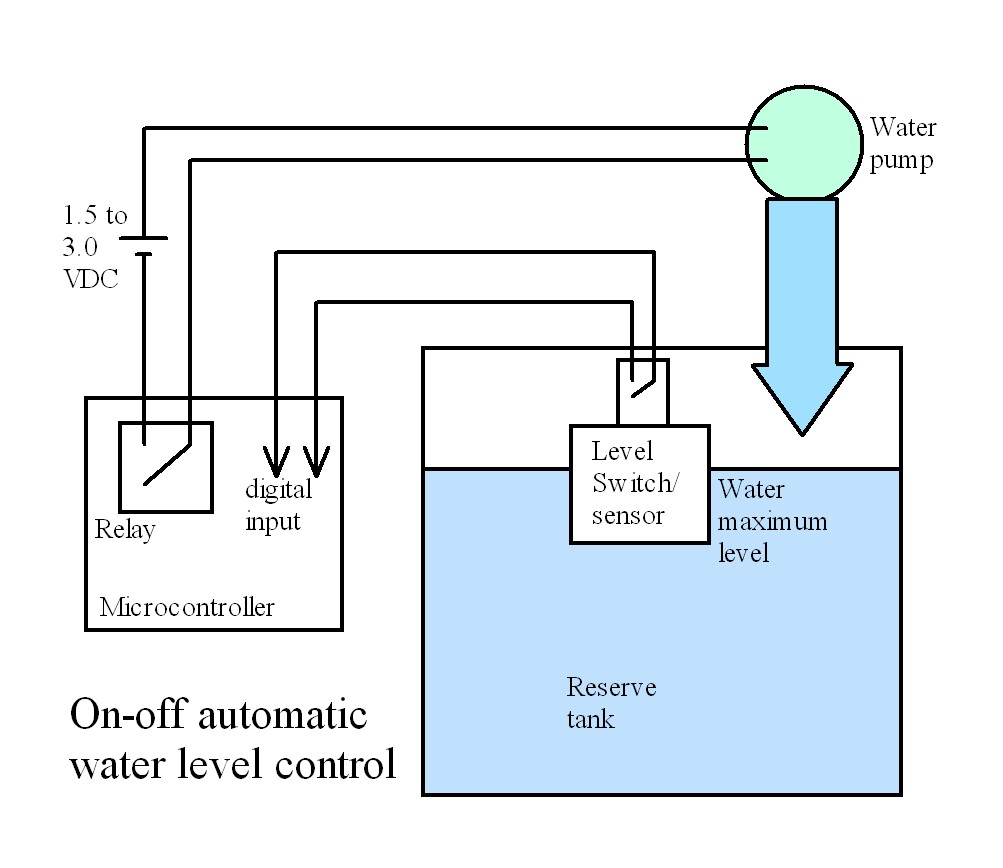

In this project, for teaching purposes,

a simple model of an on-off

automatic control filling a water container was

built, using the Bolt 18F2550 system and

the

digital level sensor RG-1045S.

The system can emulate the process repeatedly, and for this purpose includes a

storage container (see Figure 1), which

can be filled again and again through a mini water pump.

It is a control system with1 input and 1

output, ie, the microcontroller Bolt receives a

digital signal in input RC1 and,

through its relay, activate the mini water pump.

In figure 4 the simplified block diagram is shown.

The basic operation of the automatic control is as follows:

if a low water level is detected in the

container (in which case the level sensor will

close its switch), the microcontroller activates the filling

pump.

The water level will rise until the level

sensor switch opens, event that will be

detected by the microcontroller, and the

pump shuts off.

The level sensor has a hysteresis range, such that the water level starts

to decline until the switch is closed again and the mini pump

activates, repeating the filling cycle.

In the

LCD,

Bolt displays the

status of automatic control process, as shown in Figure 2.

If you want to repeat

the experiment with completely empty container control, then the

user has a two-button

manual

control (see Figure 1),

to empty or

fill the container.

For power supply of devices,

two AC/DC adapters are used, which can be

seen in the photo of Figure 1. The first supplies the

two mini water pumps 3 VDC at 1 ampere and

the second feeds the

Bolt

system with a voltage of 7.5 VDC @ 300 ma.

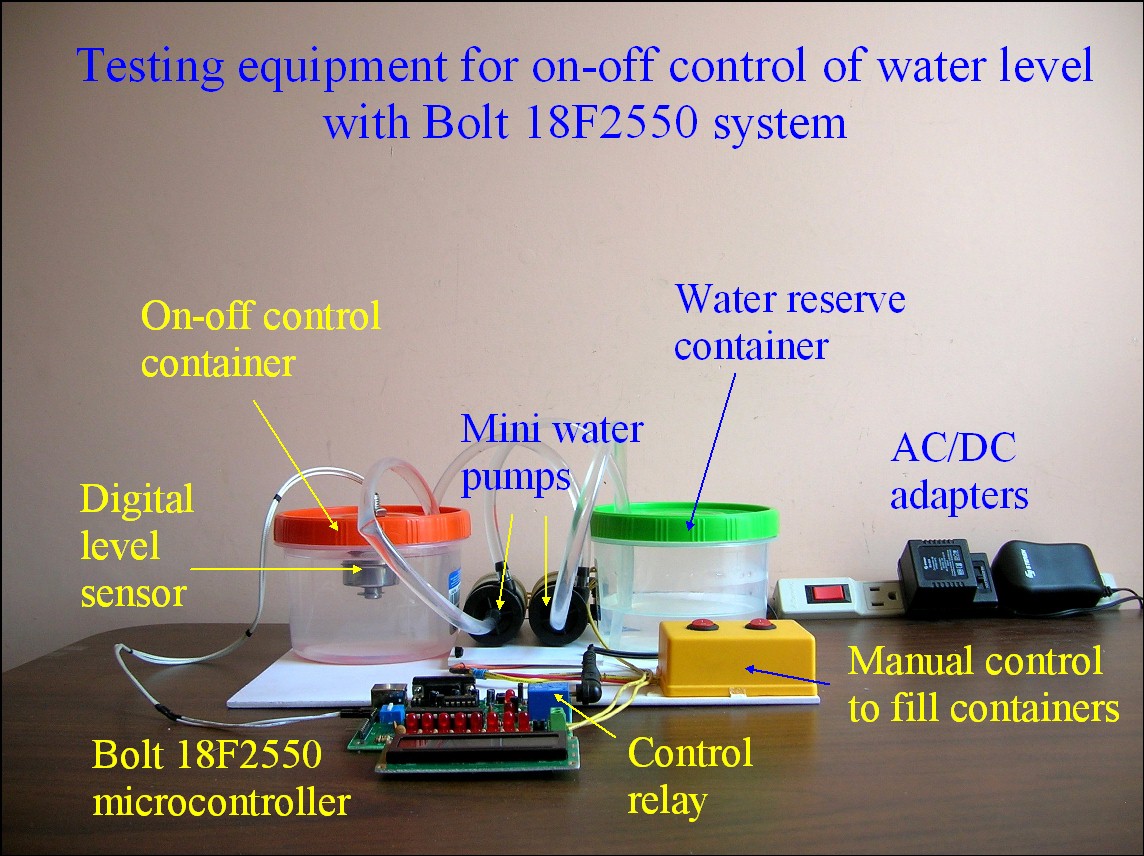

Figure 1:

Devices used in the project.

The green

cap

container

emulates what would be the cistern

and the red cap container,

the water tank that will be

filled. By means of

two buttons,

the pumps can be

activated manually

to

repeat the experiment.

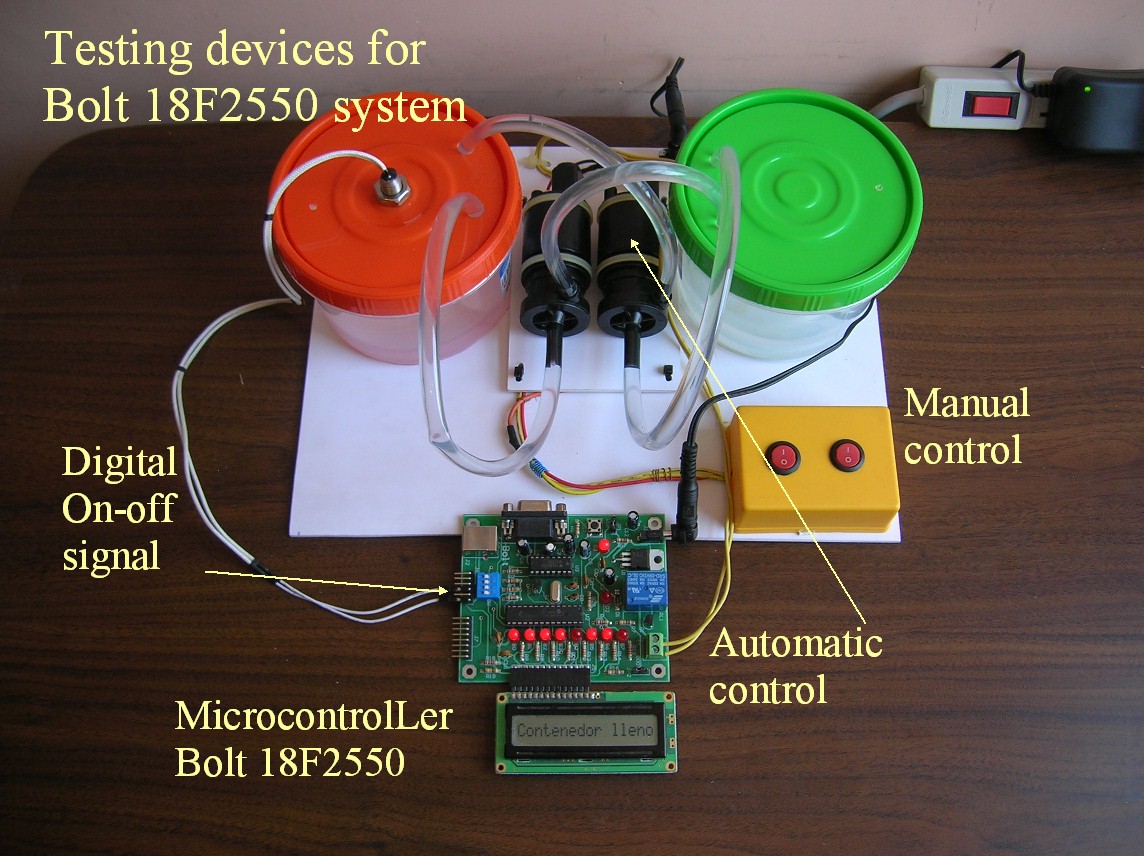

Figure 2:

Top view of the devices. The Bolt

18F2550 microcontroller system uses its

LCD display to show the

status of the process. The microcontroller

receives digital sensor signal

on pin RC1

of

the auxiliary port,

while the relay terminals

(green) are connected to the mini

pump to activate the filling of the container.

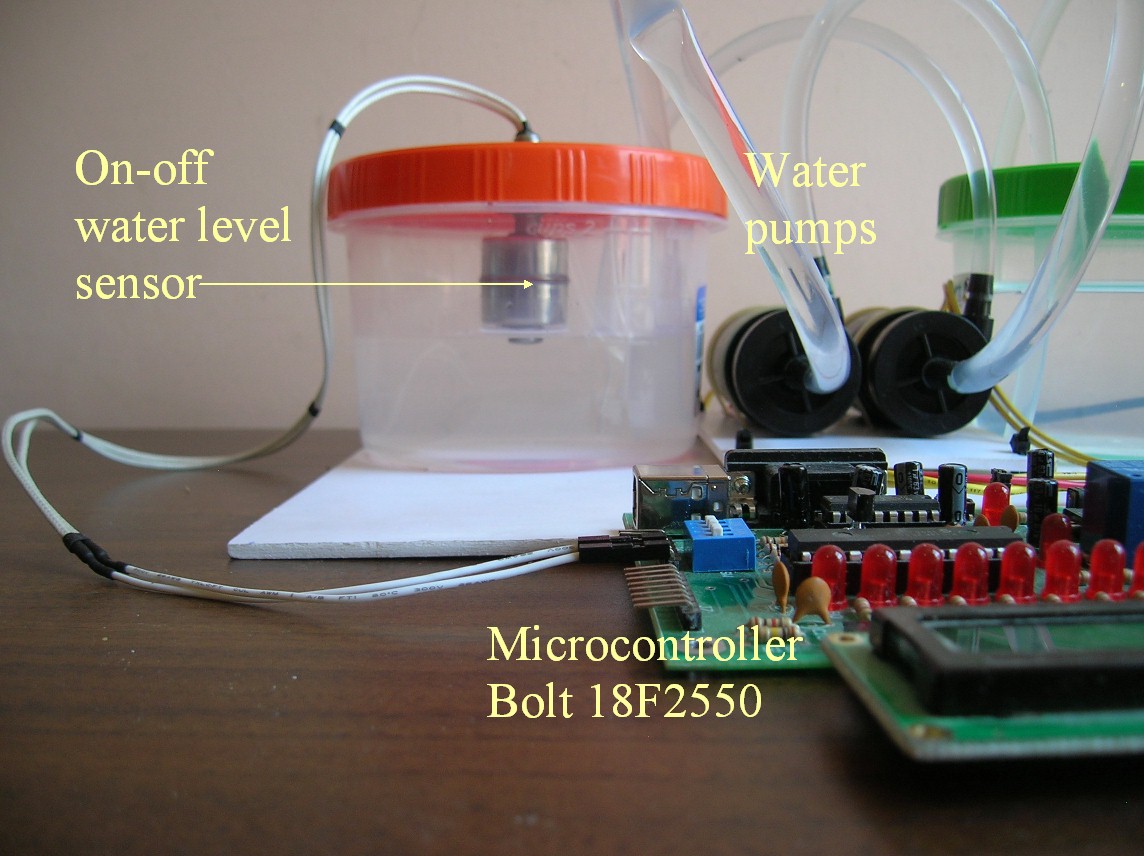

Figure 3: View

of stainless steel level sensor.

It consists of a cylindrical piece with

its hollow interior, so that

when the

water

is

reaching

the maximum level, by flotation, this piece

rises and opens the switch

contacts.

Figure 4: The

sensor can be seen as a normally closed

switch, which opens when the water

level is reached. This signal is fed to the

input RC1

of

Bolt

auxiliary port. The mini

water pump is energized with 3 VDC,

by the microcontroller relay,

as shown in Fig.

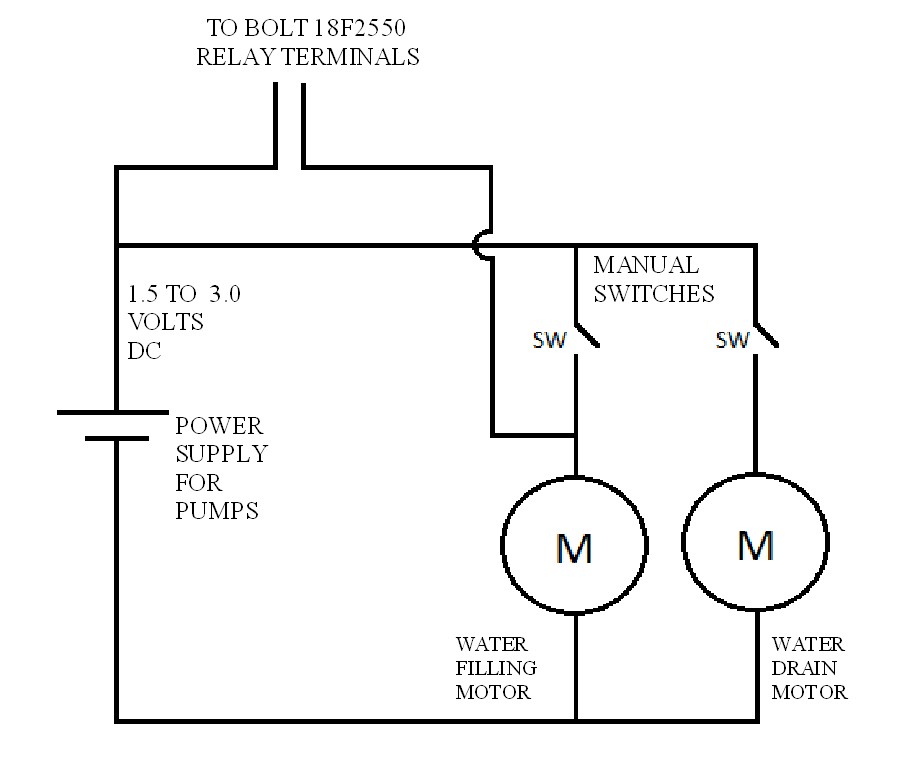

Figure 5: The

electrical connections to

activate

the two

mini water pumps are shown here. Filling

any of the containers can be

done manually by means of two switches

(SW). In automatic mode, the relay

of the

microcontroller

activates the filling pump.

Stainless steel RG-1045S water level switch

Bolt-Firmware-On-Off-Control-Water-Level.zip

|